https://dmsonline.us/wp-content/uploads/2022/06/Clickbait_2.66.3.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-08-08 06:00:002025-07-23 09:49:36Lying with Numbers

https://dmsonline.us/wp-content/uploads/2022/06/Clickbait_2.66.3.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-08-08 06:00:002025-07-23 09:49:36Lying with Numbers1.0 Introduction

The engineer delivered a shiny new FEA report, but what does it mean to you? What details to look for? Are the results good or bad? An FEA report contains much more value when all those colorful graphs reveal their meaning. Today we unveil the secrets of FEA reports. Learn the basics of their interpretation and gain much more value from that analysis you just paid for.

2.0 FEA Report

The engineer will summarize all their analysis work and results in a report. An FEA report requires some additional elements beyond standard engineering reports. The analyst starts by assuming the model is wrong. They don’t trust the FEA initially, and neither should you. The FEA report needs to demonstrate confidence in the model. Expect the following elements from the report.

- Problem description

- Analysis goals

- Geometry overview

- Describe load cases

- Evaluation criteria (applicable regulations)

- FEA Model setup

- Engineer should supply enough detail for a 3rd party to reproduce the results if needed.

- Includes constraints

- Details of each load cases

- How much geometry was modeled

- Demonstrate mesh independence

- Shows confidence in the model

- Provide results

- General overview

- Highlight any areas of interest

- Specify any areas that failed evaluation criteria

3.0 FEA Outputs

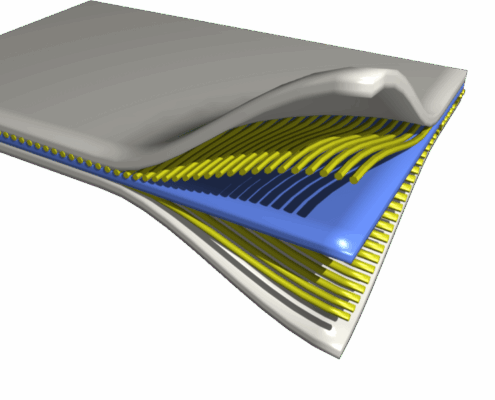

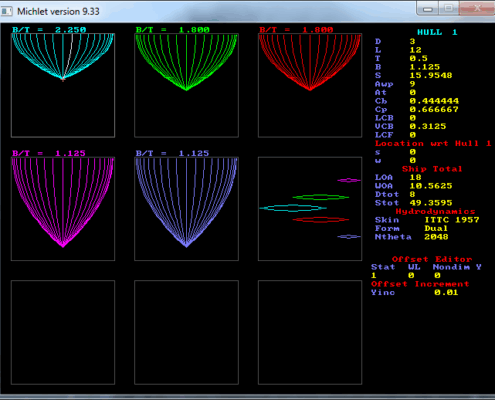

There are several different outputs that engineers use to examine FEA results. Usually the results are displayed in colorful 3D plots. Each output has its own uses.

3.1 Stress Plot

Most structural analyses ends with stresses. The stress plot is the most common output. (Figure 3‑1) We compare the stresses against some defined limit, depending on the scenario and relevant regulations. That limit is part of the information specified in the FEA report. Basically, check the entire plot and ensure nothing is above your limit.

Unfortunately, there are multiple ways to measure stress. Structures live in a 3D world, and stresses combine from three different directions. We developed different methods for combining stress to reveal different information. Skipping over the math, just remember three basic options for stress measurement:

- Von-Mises stress. This applies to most static structural analyses. Think of it as the total stress at a spot. This works for 99% of all FEA cases.

- Principal stress. We use principal stresses for fatigue analysis. Imagine this as the maximum stress in any one direction.

- Composite material stress. When working with composites, you graduated into a new level of stress complexity. There are multiple ways to measure stress and they warrant a separate discussion. Be sure to address this with your engineer when you work with composites.

3.2 Mesh Plot

The mesh plot shows the FEA mesh used in the analysis. This reveals where the elements get small and concentrate around areas of interest. Use the mesh plot for quality assurance to ensure the FEA has sufficient detail. These are especially useful when overlaid with a stress plot. The combination allows you to track how mesh density increased with stress intensity. That’s how it should work.

3.3 Displacement Plot

The displacement plot is another quality assurance tool. At the core, an FEA program solves for displacement of the nodes. Displacement is the physical distance each node moves in response to the loads. More commonly, we call this deflection. Normally, this is very small, less than a millimeter. Just check to ensure there are no major jumps in the displacement plot. If a plate moves less than a millimeter but the attached stiffener jumped by 50 mm, then you have something wrong with the FEA model.

4.0 Reviewing Your FEA Analysis

What makes results in FEA good or bad? How to use all those detailed plots? Much of the details require an experienced FEA engineer, but we all benefit from some basics.

The stress plot is very useful to examine efficient use of your structure. Steel is not free. It adds weight and fuel costs. You want to ensure the structure carries the stresses efficiently, without much excess material. An efficient structure will show a majority of the stresses near the stress limit. At least within 50% of your stress limit. Most structures have one or two stress concentrations, and those concentrations shows stresses much higher than the average stress.

Unfortunately, these minor stress concentrations often drive the material thickness and weight. An ideal structure keeps these concentrations near to the average stress levels. Or the engineer may specify reinforcements in a few key locations to avoid extra weight in the rest of the structure. Efficient structural design tries to achieve a fairly consistent stress level throughout the FEA model.

4.1 Matching Mesh to Stress

The FEA mesh rarely shows a constant element size. Instead, the mesh grows denser as the stresses change faster. When comparing the mesh to the stresses, focus on the rate of the change in the stresses. If you see a sudden spike in stress, the mesh should get very dense to match that sudden change.

4.2 Watch Out For Stress Singularities

Stress singularities are small sections where the FEA model predicts infinite stress. The model is completely wrong in these sections. They normally occur in corners, at right angled turns, and weld joints between plates and stiffeners. These are just a quirk of the FEA mathematics. You can safely ignore them. Just don’t mistake these singularities for real stress concentrations. Otherwise your structure gets unreasonably thick to cope with phantom stresses. They look the same, but have no basis in reality. It takes a skilled FEA engineer to reliably identify these spots. As the client reviewing the FEA, remember to ask about any small spots like this.

5.0 Conclusion

The FEA report contains a wealth of knowledge to those who can interpret its secrets. Those colorful graphs become incredibly informative after understanding their meaning. That is the true value of an FEA report: meaning and knowledge. Results alone are useless without appreciating their significance. And an FEA report reveals far more meaning with a little knowledge.

6.0 References

| [1] | Noads90, “Contact Analysis Of A Consumer Snap Fit Mechanism,” Wikimedia Commons, 04 Apr 2017. . Available: https://commons.wikimedia.org/wiki/File:Contact_analysis_of_a_consumer_snap_fit_mechanism.jpg. . |

| [2] | 2mentech, “Bottle Opener Comparison,” Wikimedia Commons, 6 Jun 2016. . Available: https://commons.wikimedia.org/wiki/File:Bottle_opener_comparison.jpg. . |

Share This Post

More Like This

https://dmsonline.us/wp-content/uploads/2022/06/Clickbait_2.66.3.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-08-08 06:00:002025-07-23 09:49:36Lying with Numbers

https://dmsonline.us/wp-content/uploads/2022/06/Clickbait_2.66.3.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-08-08 06:00:002025-07-23 09:49:36Lying with Numbers https://dmsonline.us/wp-content/uploads/2022/06/Clickbait_2.63.1.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-07-11 06:00:002025-08-15 10:45:34The Value of Life

https://dmsonline.us/wp-content/uploads/2022/06/Clickbait_2.63.1.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-07-11 06:00:002025-08-15 10:45:34The Value of Life https://dmsonline.us/wp-content/uploads/2021/04/Inspector.jpg

930

768

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2021-04-05 07:00:002026-03-04 09:08:57Class Societies

https://dmsonline.us/wp-content/uploads/2021/04/Inspector.jpg

930

768

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2021-04-05 07:00:002026-03-04 09:08:57Class Societies

5 Steps to (NOT) Build a Boat

Engineering Business, Hull Structure, Integration / Engineering, Production Engineering, Project Management, Shipyard And Support Services

Composite Materials

Engineering Business, Hull Structure, Materials, Special Purpose Structure, Structural https://dmsonline.us/wp-content/uploads/2020/03/M20001_Clickbait_1.png

924

1643

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2020-05-11 06:00:002026-03-04 09:09:00What is a Stability Test

https://dmsonline.us/wp-content/uploads/2020/03/M20001_Clickbait_1.png

924

1643

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2020-05-11 06:00:002026-03-04 09:09:00What is a Stability Test https://dmsonline.us/wp-content/uploads/2019/12/M19014_Clickbait3.png

810

1440

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2020-04-13 07:00:002026-03-04 09:09:01Weight Control

https://dmsonline.us/wp-content/uploads/2019/12/M19014_Clickbait3.png

810

1440

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2020-04-13 07:00:002026-03-04 09:09:01Weight Control

Underway Replenishment

Auxiliary Systems, Engineering Business, Equipment Integration, Mechanical, Mechanical Handling Systems, Piping, Replenishment Systems, Ship Control Systems, Special Purpose Mechanical Systems

Which Engineer

Design Support, Engineering Business, Hiring Consultant, Integration / Engineering, Production Engineering, Project Management, Shipyard And Support Services, Support ServicesAbout Us

Ship designs tailored to your mission. Engineering that advances profits.