Why You Want an Upgrade: Major Ship Refits

Introduction

Gaze upon that gorgeous passenger ship. A combination of efficiency, safety, and beauty. Perfection. Exactly the same as the day you first bought it. . . . Hardly! Ships change over time. Constantly update, evolve, and grow with their owner’s needs. As a naval architect, most of my effort focuses on modifications to existing vessels. Where you see a fixed asset, unchangeable; well, I see a canvas half drawn. Time to extend those lines and breathe new life into your ship. Today, let’s talk about options for major refits on a passenger ship.

Why Consider a Refit?

When I say refit, I mean more than a fresh coat of paint. This goes beyond maintenance and repairs. A refit means the boat goes into the shipyard for an extended period. We tear out the innards, cut holes in the hull, add whole new decks, and more. Refits involve a lot of new construction. New systems, new structure, major changes. So why not just build a new ship? The difference: with a refit, we don’t start from scratch. We keep the hull and most of the major systems, where 50% – 70% of the ship remains untouched. That is where the refit saves money compared to a brand new ship.

Refitting Older Ships

Usually, we plan refits for older ships, as a half measure instead of building a whole new ship. Maybe you operate on a smaller service. Not enough revenue to justify the expense of a new ship. or maybe you want to expand service by a small amount. Just an extra 25%. Not enough for a second ship, but we can build on the existing boat.

Upgrade a Used Ship (Save Money)

The second reason for a refit: save money. Ships depreciate over time. I mean, they depreciate a LOT. This factors into the price when shopping used boats. You can buy a brand new ship for $10M, or buy an older boat for only 40 – 50% of that. Even at 15-20 years old, boats remain generally the same as the new model. Pointing end still goes forward, bottom still points down and water still floats the boat. Under the right market conditions, the best financial strategy is to buy a used boat for cheap and refit that boat to make her look new.

Upgrade Aesthetics

Finally, we might refit just to update the ship aesthetics and interior. When you look upon a battered and beaten hull, full of dents, you might see a lifetime of good stories. But your customers just see a broken down junker . . . and they walk away. Appearance matters when selling to the general public. So revamp the exterior. Update to modern styles. And change the interior. Get rid of that old smoking room that no one uses. Tear down some walls and make space for a dance floor. Refits can help to update your company’s brand. Time to match the needs of the modern customer.

Correct Stability

The first need for any ship: don’t flip over. Time to talk about stability. Passenger ships meet very demanding standards for stability, to keep everyone safe. But as a ship gets older, all the changes tend to raise the vertical center of gravity. (VCG) This reduces stability. Over time, it forces us to reduce the passenger count. Less passengers means less revenue. Pretty soon, expenses outweigh revenue and the ship loses money.

To cure this problem, we increase the ship stability, using one of two major strategies: fixed ballast or sponsons. With fixed ballast, we add weight down low, near the bottom of the ship. That lowers the VCG, restoring lost stability. And we’ll use anything we can for ballast. Bricks of iron, concrete, drilling mud. Anything heavy and relatively cheap to buy. (Because we usually need a LOT of weight added.) The downside to fixed ballast: the ship has a limited weight capacity, and that fixed ballast eats into our capacity. To maintain cargo limits, we usually trade off fuel capacity. Carry less fuel onboard. For ships on short routes, like a dinner cruise or a ferry, that might be acceptable.

If not acceptable, the other option is sponsons. We build large blisters onto the side of the ship, making your hull wider. A wider hull gains more stability. This trick works to quickly add stability, without massive weight gains. You retain most of the fuel capacity. But your voyage range goes down. Those blisters pile on the hull drag. This results in higher fuel consumption and a slower top speed. Sponsons work well if your ship doesn’t travel far or moves slow. Puttering along for harbor tours, the sponsons don’t hurt much.

The end goal for all this: extra passenger count. If we regain ship stability, we regain passenger count. More passengers means more revenue. Bring those accounts back into the black and make your ship profitable.

Interior Renovation

Customers are drawn to attractive ships. With many passenger ships, the business sells an experience. Not transportation from A to B. Instead, they offer the thrill of a trip on the water. That romanticism of the sunset cruise. The carefree party with an open bar and good friends. If you want to sell that dream, you need a ship to match the vision. Time for a facelift on the old boat.

Interior renovation might mean hiring a decorator to jazz up your ship like a night club. But frequently, things get more specific to your business. I once had a client that owned a three deck passenger boat. They offered a dinner cruise with live entertainment. A good business. Except the ship layout worked against their plans.

The Problem

The ship featured a massive atrium, cutting through all three decks. Sound easily traveled between all the decks. If one deck had a party, every deck had the same party. When booking the ship, group events were all or nothing. A full booking meant 600 passengers; not easy to find groups that massive. On top of that, the kitchen sucked. They lacked the space to truly cook for 600 passengers. Everything was pre-packaged and just reheated onboard. This ship needed a new interior layout.

Now for the good news. When you look at the interior walls of a ship, relatively few walls matter structurally. Many deckhouses get built as massive open interiors, with only a few pillars in the middle. This dinner boat followed that pattern. All the decorative walls were non-structural. We can safely tear out the majority of those bulkheads and build a completely new layout.

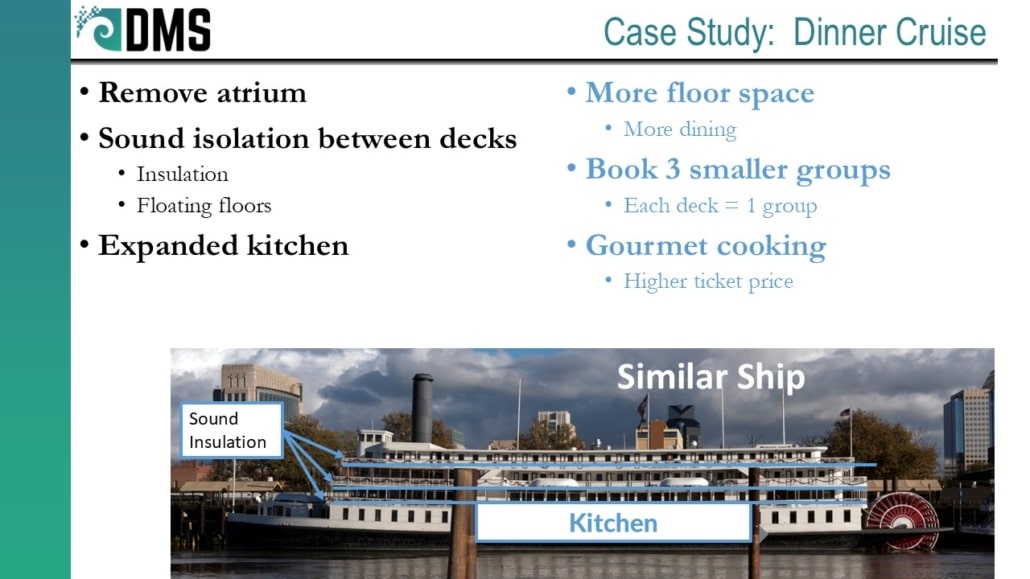

Our Solution

I developed a plan to renovate their business options. We cover over the atrium with a new floor, add doors on the stairwell and acoustically isolate each deck. Add in sound insulation and floating floors for the dance floor. Even with people dancing the night away, relatively little sound carries between each deck. We install a new entertainment system with speakers zoned to each deck. That gives us the ability to book each deck as a separate event. Run a jazz club on deck 1 and poker tournament on deck 3. Instead of locating a single group of 600 passengers, we can book 3 smaller groups on the same cruise. Smaller groups means more flexibility and more bookings.

We also planned to expand the kitchen. Add in dumbwaiters between the decks, upgrade the electric service, and expand the kitchen capacity. Plus add all the fire control systems needed for safety in a commercial kitchen. With those changes, the boat can offer gourmet cooking. Passengers pay more for a better meal. Higher ticket price keeps the ship profitable into the future.

That’s the renovation I like to work on. By changing the interior, we opened up new booking options, updated the style, improved entertainment, and increased the quality of service. Which justifies a higher ticket price. All without touching around 70% of the ship. Without major changes to onboard systems. No huge changes to the structure. With the renovation, you get a new custom designed layout at a fraction of the cost.

Lengthen The Ship

I saved the biggest for last. When you need extra space, lengthen the ship. Sounds crazy, but we do it, with a lot of careful planning. Cut the ship down the middle, pull the two halves apart, add in a new midship section to make the ship longer. However, this only works for small changes. Maybe an extra 20-30% on the ship length.

We can’t go crazy with extra length, because a longer ship requires a stronger hull. As ships get longer, the area around midships experiences the worst stresses. Thankfully, when we lengthen a ship, that section gets filled in with the new, stronger structure. But if you go too long, the existing sections will be too weak for the new ship length.

On top of the hull strength, we also need to track all the electrical and marine systems. When you cut through a hull, you also cut through hundreds of wires and dozens of pipes. We need to track each one and splice in extensions. New wire and new piping. Of course, we also check that the systems can handle that extra length. For example, extra wire might result in brownouts for the navigation system on the bridge. A sign of too long a wire run. Engineers guard against all these issues before cutting any steel.

Adding a section to the ship requires major effort. And yet, the rewards far exceed the cost. Imagine a typical passenger vessel at 120 ft long, 24 ft beam, with 2-3 decks in the deckhouse. Lengthen the ship by 20% and you gained over 1700 ft2 of new floor space. Enough room to add a restaurant. Extra seating, a larger sun deck, maybe even an arcade for the younger passengers.

To be sure, lengthening the ship is no small feat, requiring months of preparation and more months in the shipyard. But it’s the perfect solution when you need an incremental increase in capacity. Better to spend some of your money on a ship extension, instead of spending all your money on a new ship.

Conclusion

Business needs change over time, and your ship should adapt with those changes. Don’t see the ship as some immutable object. Recognize the potential for change. From minor stability corrections to major lengthening. These incremental refits become the key to maintaining your ship as the valuable asset that drives your business forward. So ask a naval architect how they can help. Come to us with a dream and half an idea. We forge those ideas into reality, keeping your ship working at its best.