https://dmsonline.us/wp-content/uploads/2025/08/Clickbait.jpg

720

1280

Nicholas Barczak

/wp-content/uploads/2025/06/DMS-logo.svg

Nicholas Barczak2025-11-11 07:00:002026-02-23 09:10:03How to Buy a Towing Tank: Purchase and Design Guide

https://dmsonline.us/wp-content/uploads/2025/08/Clickbait.jpg

720

1280

Nicholas Barczak

/wp-content/uploads/2025/06/DMS-logo.svg

Nicholas Barczak2025-11-11 07:00:002026-02-23 09:10:03How to Buy a Towing Tank: Purchase and Design GuideI love to learn how industrial equipment gets created. Boat propellers are especially interesting. Unlike ship propellers, these smaller propellers go on leisure craft and other small vessels. The emphasis is on mass production. That mass production requires an entirely different approach. But the basics are still the same. We still cast the propeller with molten metal. But the formation of the cast becomes a factory process.

We use a process called investment casting. Also called the lost wax method. We create the propeller pattern out of wax. Then coat the wax with layers of casting sand / ceramic material. Once you have enough layers built up, melt the wax. This leaves a hollow cavity to fill with cast metal.

The advantages of this process are true mass production. No need for craftsmen to spend hours on each propeller pattern. Using wax as the basis for the pattern allows us to easily capture tiny details and produce very thin casts. An excellent application for smaller parts. The downside is lack of customization. It costs a LOT to setup the machinery for this process. And the initial wax pattern needs to come from somewhere. Usually a mold, created in a customized casting operation. As you can see in the video below, this process requires high volume to become effective.

Creating Boat Propellers

Small Ship Propellers

As the propellers get larger, we shift to other casting methods. Michigan Wheel is a great example. They build propellers for both the recreational boat market, and the small ship market. The video below doesn’t explain much of the production process. But as someone that loves ships and propulsion, I have say: Who cares! Awesome propellers!

Share This Post

More Like This

https://dmsonline.us/wp-content/uploads/2025/08/Clickbait.jpg

720

1280

Nicholas Barczak

/wp-content/uploads/2025/06/DMS-logo.svg

Nicholas Barczak2025-11-11 07:00:002026-02-23 09:10:03How to Buy a Towing Tank: Purchase and Design Guide

https://dmsonline.us/wp-content/uploads/2025/08/Clickbait.jpg

720

1280

Nicholas Barczak

/wp-content/uploads/2025/06/DMS-logo.svg

Nicholas Barczak2025-11-11 07:00:002026-02-23 09:10:03How to Buy a Towing Tank: Purchase and Design Guide

Surviving the Arctic: Polar Class Icebreakers

Design Support, Fluids, Mechanical, Propulsion, Special Purpose Mechanical Systems, Structural

Ramming the Ice: Icebreaker Propulsion

Energy Generation, Fluids, Hull Structure, Propulsion, Propulsion Plant, Propulsion Units, Propulsors, Structural, Transmission and Propulsor Systems https://dmsonline.us/wp-content/uploads/2023/12/MackinawIce2-scaled-1.jpg

1200

985

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-01-16 09:00:002026-02-23 09:10:06Breaking the Ice: Icebreakers

https://dmsonline.us/wp-content/uploads/2023/12/MackinawIce2-scaled-1.jpg

1200

985

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

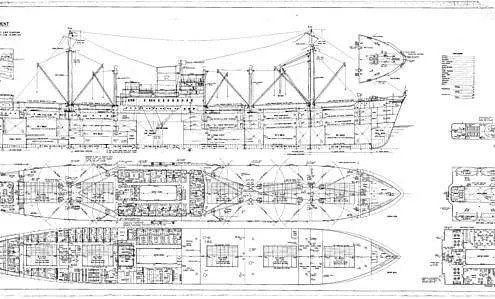

Nate Riggins2024-01-16 09:00:002026-02-23 09:10:06Breaking the Ice: Icebreakers https://dmsonline.us/wp-content/uploads/2022/06/MVAltairGeneralArrangementPlan_SmallResolution.webp

299

640

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-09-12 06:00:002025-09-30 07:31:20How to Design a Ship

https://dmsonline.us/wp-content/uploads/2022/06/MVAltairGeneralArrangementPlan_SmallResolution.webp

299

640

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-09-12 06:00:002025-09-30 07:31:20How to Design a Ship

How Propulsion Works: Classifying Ship Propulsion

Propulsion, Propulsion Plant, Propulsors, Waterjet Propulsors

Ever Given: What We Don’t Know

Command and Surveillance, Fluid Dynamics, Miscellaneous, Ship Maneuvering, Ship Motion Control, Ship Response https://dmsonline.us/wp-content/uploads/2022/02/ClickBait1_1.84.1.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-02-21 06:00:002025-08-15 13:17:02Stability Letters Explained

https://dmsonline.us/wp-content/uploads/2022/02/ClickBait1_1.84.1.jpg

1080

1920

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-02-21 06:00:002025-08-15 13:17:02Stability Letters Explained

Three Neat Tricks with Marine Cranes

Masts, Kingposts, Service Platforms, Mechanical, Mechanical Handling SystemsAbout Us

Ship designs tailored to your mission. Engineering that advances profits.