https://dmsonline.us/wp-content/uploads/2023/12/HabbakukCover-Small-1.jpg

489

500

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-09-24 09:18:002026-02-23 09:10:05Project Habbakuk: A Ship from Ice!

https://dmsonline.us/wp-content/uploads/2023/12/HabbakukCover-Small-1.jpg

489

500

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-09-24 09:18:002026-02-23 09:10:05Project Habbakuk: A Ship from Ice!1.0 Introduction

Finite Element Analysis (FEA). How does it happen? What is the general process for how to produce a quality FEA analysis, from start to finish? As a client, what do you get when you pay for FEA? No one should become an expert just to purchase FEA services, but we all do benefit from a basic knowledge of the FEA process.

2.0 FEA Process

It’s good to know the general FEA process. This allows you to negotiate with reasonable expectations and understand the limitations of your service provider. Figure 2‑1 shows the general work sequence that an FEA analyst goes through.

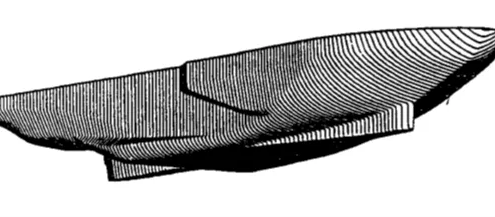

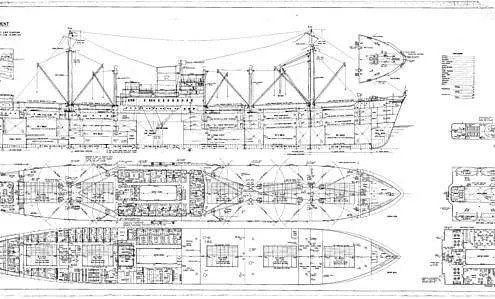

2.1 Geometry / Problem Definition

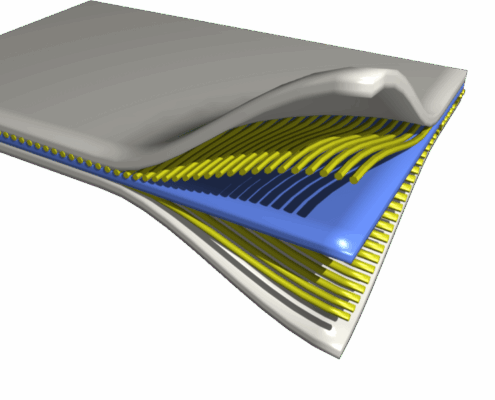

The geometry is where it all starts. Eventually, the engineer will need to build an accurate 3D model for the FEA analysis. They will need any geometry that defines the ship section. If you wish to install new equipment, the engineer needs the details about that equipment, and the structural details of the ship at the installation location. The engineer will likely need to build a new 3D model specific to the FEA, even if you supply a 3D model as a starting point. This is for three main reasons:

- Software programs are not always compatible. Your 3D model may be unreadable by the FEA program.

- FEA programs read 3D models differently than humans. A model that looks perfectly normal to a human may hide many tiny errors in the measurements and part definitions. Those are all errors that an FEA engineer needs to fix before starting the analysis.

- The engineer usually modifies the model with several simplifications that help in the analysis stage.

2.2 Specify Loads and Constraints

Next the engineer constrains the model, specifying sections where the structure cannot move. We use these constraints to define the conditions at the edges of the FEA model. After constraints, the loads specify all the actions on the model. This may be any of a number of things:

- Weight from a crane load

- Hydrostatic pressure from water

- Acceleration from ship motions

- Earth static gravity

- Thermal expansion from heat

Remember that in most cases, you will need more than one load case. Normally the engineer needs to check several different load combinations. Part of their work is to define all those load cases, check if any more are required.

2.3 Mesh Generation

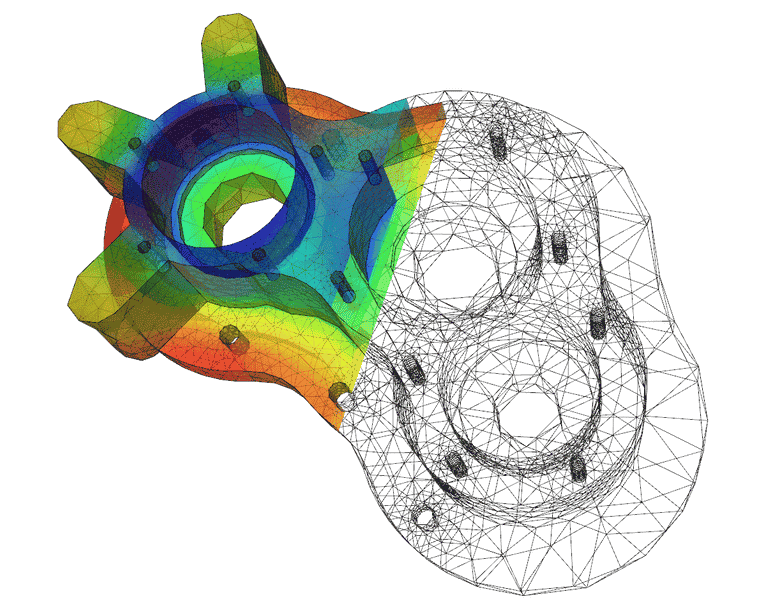

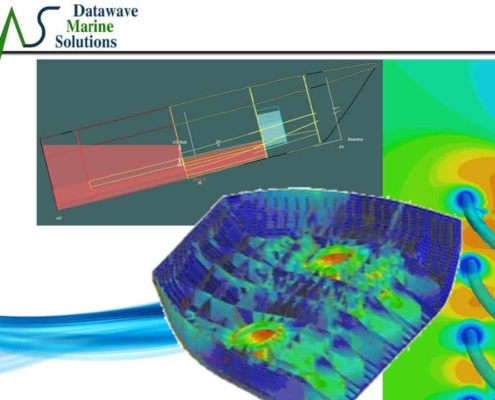

The mesh is what drives the magic of FEA. (Figure 2‑2) Take a big complicated ship and break it into many tiny little pieces. The engineer tries to minimize the cell count in the mesh by focusing small cells only where required. More cells mean more computing time and higher budgets. By current standards (2018):

- 30,000 – 100,000 cells makes a medium analysis that can run on a decent desktop.

- One million to three million cells is a big FEA model, requiring extended computing time.

- Three million and up means large models where the computing time will probably be its own item in the budget.

You can expect the engineer to generate multiple meshes. Getting the right mesh is partly trial and error. And multiple meshes are required for the mesh convergence study.

2.4 Mesh Convergence Study

The haunting question of any mesh generation: what is the right size for the mesh. We all have guidelines, but no one can predict the exact size of cell required for each FEA analysis. True certainty requires the engineer to run a mesh convergence study. Also called a mesh independence study, this should be included as part of the standard FEA analysis. The mesh convergence study is a major part of the quality control for the FEA.

2.5 Check Against Simplified Classic Model

As part of the quality control, the engineer develops some simplified hand calculations and compares them to the FEA predictions. These hand calculations provide a sensibility check. The FEA should definitely be more accurate, but any outputs are still within the same range as the hand calculations. These calculations rarely make it into the final report. They just form part of the quality control that allows you to confidently trust the FEA.

2.6 Generate Requested Results

The model works! Now to create the actual requested outputs. This takes a surprising amount of time. Normally the FEA results go into a report, and the report requires a shocking number of 2D pictures to show every detail of a 3D model. Typically, the engineer provides several overview pictures and then focuses on the few details of interest in the model.

Some software allows the engineer to provide results as a 3D file that you can view with a free viewer. Ask if you can get this option. This may be a good compromise that allows you to see all the details and saves the engineer from spending hours generating photos.

2.7 Write Report

Finally, the engineer should summarize all their analysis work and results in a report. An FEA report has a few additional requirements beyond standard engineering reports. The FEA report needs to demonstrate reason for confidence in the model. Expect the following elements from the report:

- Problem description

- Analysis goals

- Geometry overview

- Describe load cases

- Evaluation criteria (applicable regulations)

- FEA Model setup

- Engineer should supply enough detail for a 3rd party to reproduce the results if needed.

- Includes constraints

- Details of each load cases

- How much geometry was modeled

- Demonstrate mesh independence

- Shows confidence in the model

- Provide results

- General overview

- Highlight any areas of interest

- Specify any areas that failed evaluation criteria

One major contention: clients sometimes want a copy of the FEA model. This is the equivalent of asking a doctor if you can perform your own X-rays. Engineers tend to resist because the FEA model also contains all their proprietary settings. Plus you need the same FEA software to even open the file. Most engineers prefer to hold back their model, but they usually provide it to 3rd parties for review. For example: send the model to ABS for review by class society. These requests go smoother if you identify a specific reason for the engineer to provide a copy of the model.

3.0 Conclusion

Finite Element Analysis (FEA). The process. The science. You don’t need expertise to benefit from FEA services. The engineer delivers all that background knowledge wrapped into a tidy report. But we all benefit from a basic understanding of the process and applications. Begin with reasonable expectations for an FEA analysis and monitor with an understanding of the overall process.

4.0 References

| [1] | U. A1, “Elmer Pump Heat Equation,” Wikimedia Commons, 2 Jun 2010. . Available: https://commons.wikimedia.org/wiki/File:Elmer-pump-heatequation.png. . |

| [2] | Dcoetzee, “Block Matrix Multiplication,” Wikimedia Commons, 4 Sep 2012. . Available: https://commons.wikimedia.org/wiki/File:Block_matrix_multiplication.svg. . |

Share This Post

More Like This

https://dmsonline.us/wp-content/uploads/2023/12/HabbakukCover-Small-1.jpg

489

500

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-09-24 09:18:002026-02-23 09:10:05Project Habbakuk: A Ship from Ice!

https://dmsonline.us/wp-content/uploads/2023/12/HabbakukCover-Small-1.jpg

489

500

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-09-24 09:18:002026-02-23 09:10:05Project Habbakuk: A Ship from Ice! https://dmsonline.us/wp-content/uploads/2023/12/Icebreaker_SpoonBow.webp

217

598

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-07-16 09:00:002026-02-23 09:10:05Strong as Ice: Icebreaker Structure

https://dmsonline.us/wp-content/uploads/2023/12/Icebreaker_SpoonBow.webp

217

598

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-07-16 09:00:002026-02-23 09:10:05Strong as Ice: Icebreaker Structure

Surviving the Arctic: Polar Class Icebreakers

Design Support, Fluids, Mechanical, Propulsion, Special Purpose Mechanical Systems, Structural

Ramming the Ice: Icebreaker Propulsion

Energy Generation, Fluids, Hull Structure, Propulsion, Propulsion Plant, Propulsion Units, Propulsors, Structural, Transmission and Propulsor Systems https://dmsonline.us/wp-content/uploads/2023/12/MackinawIce2-scaled-1.jpg

1200

985

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-01-16 09:00:002026-02-23 09:10:06Breaking the Ice: Icebreakers

https://dmsonline.us/wp-content/uploads/2023/12/MackinawIce2-scaled-1.jpg

1200

985

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-01-16 09:00:002026-02-23 09:10:06Breaking the Ice: Icebreakers https://dmsonline.us/wp-content/uploads/2022/06/MVAltairGeneralArrangementPlan_SmallResolution.webp

299

640

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-09-12 06:00:002025-09-30 07:31:20How to Design a Ship

https://dmsonline.us/wp-content/uploads/2022/06/MVAltairGeneralArrangementPlan_SmallResolution.webp

299

640

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-09-12 06:00:002025-09-30 07:31:20How to Design a Ship

Composite Materials

Engineering Business, Hull Structure, Materials, Special Purpose Structure, Structural

Six Ways to Break the Ship

Elastic Static Loading, Fatigue, FEA / Numerical Methods, Hull Decks, Hull Structural Bulkheads, Hull Structure, Masts, Kingposts, Service Platforms, Shell and Supporting Structure, Special Methods, Special Purpose Structure, Structural

Improve Engineering Value

3D Modeling, Arrangements, Drafting, Engineering Business, Fatigue, FEA / Numerical Methods, Fluid Dynamics, Fluids, Fluids Special Methods, Hull Structure, Hydrostatics, StructuralAbout Us

Ship designs tailored to your mission. Engineering that advances profits.