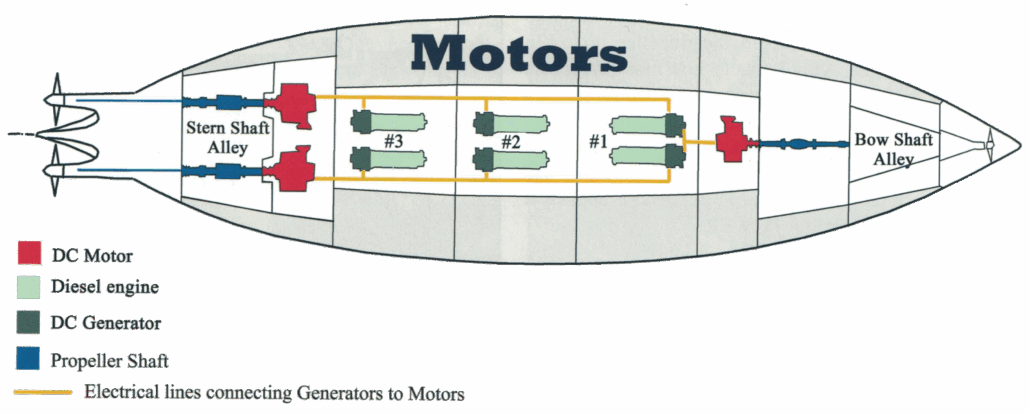

The Mackinaw was built in 1944, in the infancy of modern industrial electric motors. Back then, practically every ship had the same answer: diesel driven engine directly coupled to the propeller. So why did the Mackinaw take on the risk of new electric motors? The vessel had six diesel engines, each driving DC generators. These generators then fed into three DC electric motors, which drove the propellers. (Figure 4‑1) There was no direct link between engine and propeller. But why add all this complexity?

Despite the risk of newfangled electric motors, electric propulsion offers abundant benefits for an icebreaker. The first was engine room layout. When engines directly connect to the propeller, we need a straight shaft line between the propeller and the engine. For an icebreaker, this gets especially problematic. The propeller position places engines low in the hull when connected with a shaft line. And icebreakers use especially rounded hulls, with very little space near the bottom.

“If you don’t have diesel-electric, you need a mechanical link all the way from your engines to your shaft. That means your engines have to be down low and back, fairly close to where your shaft goes through the hull. With diesel-electric you can position your engines anywhere.”

Don Witt, Senior Chief Electrician [1]

The flexibility of engine placement adds a safety feature. Notice the engines were separated into three pairs, each in their own compartment. If an engine room floods, the other two compartments remain watertight, with their engines fully operational. That makes it extremely unlikely that you completely lose power. Each engine can feed power to any of the electric motors, meaning you need to destroy all three motors to completely lose propulsion. For anything less than flooding the entire ship, chances are good that you can find some combination of engine and electric motor to control the ship.

That flexibility also helps with maintenance and efficiency. We don’t need to stop the ship for maintenance on a single engine. Just run on reduced power. Also useful for slow steaming. Sometimes the ship doesn’t need full power, but these engines get extremely inefficient it you try to run them at a low throttle. Instead, completely turn off an engine, leaving the remaining beasts roaring at full power and peak efficiency. The flexibility of diesel electric decouples engineering from ship operations.