https://dmsonline.us/wp-content/uploads/2023/12/HabbakukCover-Small-1.jpg

489

500

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-09-24 09:18:002026-02-20 09:08:57Project Habbakuk: A Ship from Ice!

https://dmsonline.us/wp-content/uploads/2023/12/HabbakukCover-Small-1.jpg

489

500

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-09-24 09:18:002026-02-20 09:08:57Project Habbakuk: A Ship from Ice!1.0 Introduction

How do you build a ship’s propeller? Propellers come in all sizes. The really fun ones are as big as a house! (Figure 1‑1) And many of them are a single piece of metal. No seams. No bolts. No welds. A bronze alloy that just began its life in the shape of a perfect propeller. So how do you build a perfect propeller the size of a house?

2.0 Casting a Propeller

Many large propellers are actually a single piece of bronze alloy. They are formed by casting the entire propeller in one go. In casting, you pour molten metal into a mold. Let the metal cool, and out pops a solid metal part.

Things are slightly different when you need to cast something the size of a house. You have to account for several new complications.

- The casting must be strong enough to support the weight of all that metal

- Big casting means a lot of air in the mold, all of which must escape

- You must control how quickly the casting cools. Otherwise the final solid metal is not strong enough.

- The inside of the casting cools much slower than the outside.

- The entire mold actually expands slightly due to thermal expansion.

- Everything is SUPER HOT! That giant lump of metal puts out tons of heat.

- The entire thing is very heavy. How do you move it?

Check out this video which highlights the process of casting and machining a finished propeller blade.

3.0 Making the Propeller Pattern

We know that casting involves pouring liquid metal into a mold. Backup a second. How did we get the shape for that mold? The first step in any casting is making a pattern. This is a wooden shape that we use to form a mold. These patterns involve some combination of computer controlled machining and hand work to create an absolutely flawless shape. Have you noticed how complex the shape of a propeller is? Not a straight line anywhere on the entire thing. Curves, all of it. And always changing shape. All this adds up to hours and hours of work for that final, flawless pattern.

4.0 Conclusion

Propellers are big industry. They are hard to envision. Harder to make, and hardest yet to get perfect. When you catch a glimpse of that shining bronze at the stern of a ship, don’t take it for granted. In those whirling blades, I see the endless cycles towards the pursuit of complete perfection.

Share This Post

More Like This

https://dmsonline.us/wp-content/uploads/2023/12/HabbakukCover-Small-1.jpg

489

500

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-09-24 09:18:002026-02-20 09:08:57Project Habbakuk: A Ship from Ice!

https://dmsonline.us/wp-content/uploads/2023/12/HabbakukCover-Small-1.jpg

489

500

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-09-24 09:18:002026-02-20 09:08:57Project Habbakuk: A Ship from Ice! https://dmsonline.us/wp-content/uploads/2023/12/Icebreaker_SpoonBow.webp

217

598

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-07-16 09:00:002026-02-20 09:08:58Strong as Ice: Icebreaker Structure

https://dmsonline.us/wp-content/uploads/2023/12/Icebreaker_SpoonBow.webp

217

598

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-07-16 09:00:002026-02-20 09:08:58Strong as Ice: Icebreaker Structure

Surviving the Arctic: Polar Class Icebreakers

Design Support, Fluids, Mechanical, Propulsion, Special Purpose Mechanical Systems, Structural

Ramming the Ice: Icebreaker Propulsion

Energy Generation, Fluids, Hull Structure, Propulsion, Propulsion Plant, Propulsion Units, Propulsors, Structural, Transmission and Propulsor Systems https://dmsonline.us/wp-content/uploads/2023/12/MackinawIce2-scaled-1.jpg

1200

985

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-01-16 09:00:002026-02-20 09:08:58Breaking the Ice: Icebreakers

https://dmsonline.us/wp-content/uploads/2023/12/MackinawIce2-scaled-1.jpg

1200

985

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-01-16 09:00:002026-02-20 09:08:58Breaking the Ice: Icebreakers https://dmsonline.us/wp-content/uploads/2022/06/MVAltairGeneralArrangementPlan_SmallResolution.webp

299

640

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

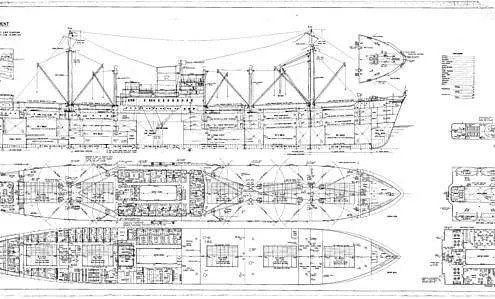

Nate Riggins2022-09-12 06:00:002025-09-30 07:31:20How to Design a Ship

https://dmsonline.us/wp-content/uploads/2022/06/MVAltairGeneralArrangementPlan_SmallResolution.webp

299

640

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-09-12 06:00:002025-09-30 07:31:20How to Design a Ship

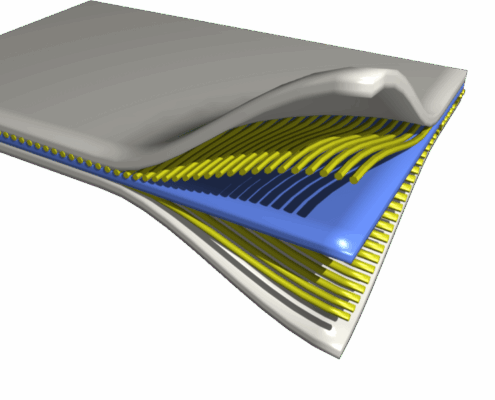

Composite Materials

Engineering Business, Hull Structure, Materials, Special Purpose Structure, Structural

Six Ways to Break the Ship

Elastic Static Loading, Fatigue, FEA / Numerical Methods, Hull Decks, Hull Structural Bulkheads, Hull Structure, Masts, Kingposts, Service Platforms, Shell and Supporting Structure, Special Methods, Special Purpose Structure, Structural

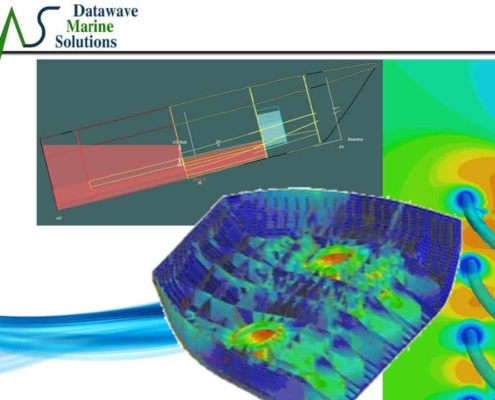

Improve Engineering Value

3D Modeling, Arrangements, Drafting, Engineering Business, Fatigue, FEA / Numerical Methods, Fluid Dynamics, Fluids, Fluids Special Methods, Hull Structure, Hydrostatics, StructuralAbout Us

Ship designs tailored to your mission. Engineering that advances profits.