What to Buy for a Towing Tank: Shopping List for Components

Introduction

Time to buy a new towing tank! Let me just open my mail order catalog and flip to page 55. I’m partial the Ranier model 228, what about you? I mean COME ON! You can’t order a ready built towing tank, outside of a few demonstration models used in classrooms. Every commercial tank emerges as a collection of components from a dozen different vendors. Something very intimidating. Where do you start shopping on that massive list? What do you even need to buy?

Break down the list into the major equipment, and the towing tank gets much less scary. So let’s cover all the major equipment in a towing tank. Armed with this knowledge, you know where to start shopping for your next towing tank.

Typical Equipment

When you think of a towing tank, you may imagine a stack of expensive scientific equipment. And that’s part of the mix. But much of the equipment just addresses practical matters. For example, you need a concrete basin to hold the water. And some pipes to empty and fill the tank. Simple, practical issues. Looking at the normal concerns, Table 2‑1 lists the typical equipment in a towing tank.

Table 2‑1: Typical Equipment in Towing Tank

| Equipment | Purpose |

| Water flume | The physical concrete basin that holds the water. Make sure the basin can handle the hydrostatic pressure of the tank. |

| Water filtration | Need to prevent biological growth, and filter out fine particles. Even the purest city water will introduce a lot of particulates. |

| Facilities to fill and empty water flume | Every 1-2 years, the tank will completely replace their water. Millions of gallons water. We need dedicated piping to perform this. |

| End beach | When we generate waves that travel down the towing tank, we need to dissipate and dampen out those waves. The beach at the other end achieves this (sometimes poorly). The ability to design a good beach is a hallmark of skill. Many tanks have also switched to placing wavemakers at both ends and using the wavemaker as active wave absorbers to damping out the waves quicker. |

| Side beaches | Some tanks have side beaches. As the model goes down the tank, it generates waves that move sideways, out from centerline. The side beaches attempt to dampen these. I have seen everything from dedicated wooden boards to pool noodles. The side beaches also need to be something we can retract. They interfere when we want to use the wavemaker. |

| Wavemaker | The wavemaker creates waves for testing against the model. |

| Towing carriage | |

| Carriage structure | Think of this as the moving lab. The carriage contains all the computers and sensors. It also holds the test model. Test personnel will travel on the carriage. |

| Velocity controller | Velocity control is key. The carriage needs to hold a set velocity with less than 0.1% deviation. And it needs to achieve this for all prescribed speeds. The velocity controller will include prescribed acceleration phases and then hold steady velocity. |

| Power supply | Power lines conduct power to the carriage. We need to connect high amperage power to a moving platform. Typically need to supply 3 phase 480V for the motors and 1 phase 120V for the computers. |

| Carriage rails | Carriage rails need to be laser straight and level the entire length. Ground perfectly smooth. For long tanks, the rails also need to bend with the curvature of the Earth to remain perfectly parallel to the water. |

| Safety stops | The carriage will include physical triggers along the tank to trigger regular stops and emergency stops. |

| Data acquisition system | |

| Computers | Expect at least two custom PC’s and numerous monitors. We need to mount them, supply power, and manage the cables. |

| Sensors | The sensors convert physical measurements into electrical signals for the data acquisition system. The sensors are very expensive. They measure everything from force to movement. Expect 6-20 sensors depending on the required experiments. |

| Primary dynamometer | The primary dynamometer measures forces on the model. This is the best sensor in the entire towing tank. This needs an error of 0.2% or less. Expect to spend $10k – $30k (USD) on the dynamometer alone. |

| Motion sensors | The motion sensors record the vessel motions (trim, heave, pitch, roll, etc.) This happens while the dynamometer records the vessel forces. |

| Wave probes | The wave probes record water elevation as waves pass by. A tank will normally include numerous wave probes. Some attached directly to the wavemaker. Some stationed along the towing tank. And some mounted to the tow carriage. |

| Time synchronization | A towing tank collects data from dozens of sensors, translated through computers from several different vendors. We want to view a synchronized data record afterwards. The system may actually require a dedicated chronometer to synchronize the time with other vendor systems. |

| Additional inputs / outputs | The system needs to expand for future uses. This means a method to easily plug in new sensors. Manage the chaos of wires. The systems needs additional analog channels to receive data. A few digital channels to receive triggers for data acquisition. Some outputs to possibly control model systems. |

| Additional video monitors | A typical carriage is physically divided into two sides. The operators are on one side, and they have all the monitors and computer controls. Observers are on the other side. It is very nice to place additional monitors so the observers can see the same data without moving to the operator side. |

| Lighting | |

| Carriage lighting | Lighting on top of the carriage for the people to work. Lighting in the main tank is often very sparse, with the primary work lights traveling on the carriage. |

| Under carriage lighting | We want to see the model. But the carriage structure shadows the model. So, we include dedicated waterproof lights directly under the carriage to illuminate the model. |

| Model Cameras | You don’t get a very good view of the model from on top of the carriage. So, we have dedicated cameras underneath the carriage to view the model in testing. There may be additional cameras stationed throughout the tank. |

| Recording equipment | We want to record the video of the model test. This will need to time synchronize with the rest of the experiment data. |

| Motion capture | Many tanks now have the ability to track vessel motions of a free running model using cameras and locator balls. It’s a simple system to include, and adds a lot for experimental capabilities. |

| Software | So much software to run all these parts. |

| Data acquisition system | This reads all your sensors and converts it to a digital file stored on the hard drive. Most software is extremely flexible, allowing you to build your own custom setup. |

| Tow carriage controller | We’ve gone past “GO” and “STOP”. The software allows you to specify a precise velocity profile during the length of carriage travel. |

| Wavemaker control | Wavemaker software allows us to specify a spectrum of waves, and the software determines the power and inputs to the paddles on the wavemaker. |

| Video editing software | With all that video, you need some way to cut out the useless bits and trim things down to a good presentation. |

| Camera control software | We want to change the camera. Focus on different sections of the model. Remote control makes this easy. |

| Open water propeller dynamometer | We also test the open water performance of propellers in a towing carriage. The dynamometer is a strut mounted under the carriage. It spins the propeller at a prescribed speed. Then we measure the thrust and torque from the propeller. |

| Self propulsion dynamometer | For the self propulsion test, we mount the propeller on the model. We then tow the model and test at different rotation speeds of the propeller. This dynamometer needs to rotate the propeller at a specified speed. It also needs to accurately measure RPM and torque on the propeller. It needs to be very small to fit inside the model. And we normally need two of them, because most ships have two propellers. |

Wavemaker

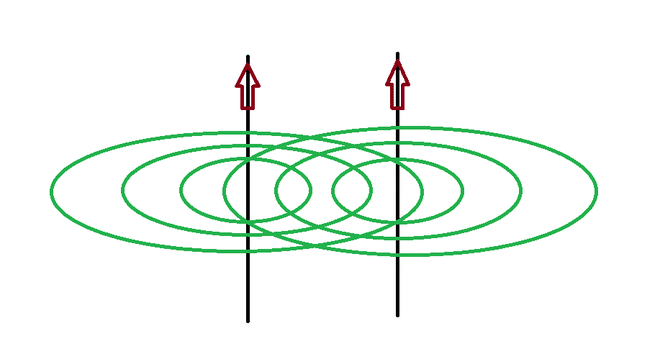

The style of wavemaker varies depending on the type of waves to model. You can choose between deep water or shallow water waves. In most cases, we want to model deep water waves. The key is that waves involve movement of water particles across the entire depth of the towing tank. Not just on the surface. In deep water waves, the particle velocity tapers off with increased depth, following exponential decay. The linear distribution of flap style wavemakers provides a suitable approximation for deep water waves.

With shallow water waves, we don’t get that decay with water depth, because of the shallow depth. To model shallow water waves, our wavemaker uses a flat paddle that directly moves forward and backward. No hinge and no tapering with water depth.

Modern wavemakers also come with multiple paddles, spread across the width of the tank. Your typical wavemaker may include 6 paddles, each independently controlled. This allows us to correct for interference from the side walls. Those walls generate friction, meaning the edges of the wave slow down and fall behind the center. By slightly adjusting each paddle motion, we correct for this friction effect. We can also angle our waves slightly by creating a time delay between the paddles. Sometimes useful for different experiments.

When asking about wavemakers and quality, focus on the transfer function. This is the ratio that converts from wavemaker paddle movement to generated wave amplitude. It varies depending on the wave settings. We need to calibrate the transfer function for each towing tank. And most importantly, we want that transfer function to remain constant despite small variations in tank depth and despite position along the length of the tank.

The skill of the manufacturer shows in the consistency of this transfer function. Any idiot can make a flap wavemaker. Take a sheet of stainless steel, mount it on some pins and attach an electric actuator. Easy. The real skill lies in the PID controls and sensor feedback that controls the actuator. Each wavemaker paddle needs to account for its own waves, but also the waves generated by the neighboring paddles.

In addition, a lot goes into generating a truly random wave spectrum for irregular waves. First, they program the wavemaker to reliably generate regular waves. The ability to produce a single wave at a single amplitude. That forms the basic framework for wavemakers. But then we want to generate irregular waves. These require an input wave spectrum. And a randomized set of wave frequencies and phase angles. How exactly do they conduct that randomization while still reliably producing the requested wave spectrum. Here lies another mark of skill.

Towing Carriage

It’s all about vibration. When designing the towing carriage, we are not concerned about strength. Our primary concern is stiffness and vibrations. The carriage needs to act as a fixed reference for the experiment. We need extreme stiffness to limit deflections of the carriage structure. Especially at the tow post. If that carriage flexed vertically by a millimeter at the tow post, it introduces massive error. Everything on the carriage will be oversized for the sake of stiffness.

The second problem is vibration. The towing carriage produces vibrations as it travels down the tank rails. These vibrations appear in the sensor measurements and contaminate the data. We can’t avoid vibrations, as much as we would like to. The strategy here is to limit the magnitude of vibration and control its frequency. Most sensors in a towing tank measure items at low frequency. Below 100 Hz. Normally below 30 Hz for steady state events. So, we want to ensure that any resonant frequencies with the towing carriage are well above that measurement range. If all the vibrations from the carriage happen at high frequency, we can filter that out from the measurements.

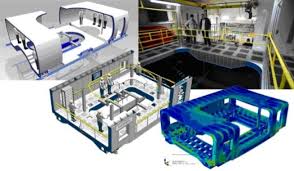

Finite element analysis (FEA) is useful here. Expect an FEA model of the carriage as part of the design effort. That FEA model will check for resonant frequencies and check response of the carriage to random frequency vibrations.

Despite best efforts, random vibrations still happen. Even by controlling the resonant frequency of the carriage, some low frequency vibrations will get through to the sensors. So, we need to limit the magnitude of vibration.

- Carriage rails will be mounted on 2 axis adjustable blocks. (These are the rails that the carriage rides on.) After construction, we need to align the carriage rails vertically and horizontally. Over a short distance, this can be done with laser alignment. Over a longer distance, we need to account for the curvature of the Earth. The rails need to remain parallel to the water surface, not to the ground.

- We also need to grind smooth all the welded joints on the carriage rails.

- The wheels on the towing carriage need to be carefully mounted to limit deflection and vibration.

- Expect that the main mount for the tow post will have additional vibration isolation mounts to isolate this from the main carriage.

Flexibility

Every towing carriage I visited always had at least one apparatus held on with nothing more than temporary clamps. This underpins the importance of flexibility. The mounting requirements and equipment will change drastically throughout the carriage’s lifetime. It’s advisable to include T-track rails so we can bolt random equipment to the carriage. Correction. It’s advisable to include an ungodly number of T-track rails located everywhere on the carriage. More T-track rails than you thought humanly possible.

Also include additional wire runs. And make the entire carriage easy to access and modify. Remember that most of the modifications and additions will happen at the underside of the carriage.

Electrical Systems

The towing carriage supplies power to our data acquisition system, a very sensitive set of electrical equipment. These sensors detect the gentle tap of your foot from 10 feet away. With the data acquisition system, all sensors eventually turn into electrical signals. This means our data acquisition system is extremely sensitive to electrical interference. Even fluctuations of a few millivolts introduce noise into the measurements.

That becomes a problem when considering the reference voltage. The system works by measuring voltage difference across the sensors. But what do you use as the reference for 0V? Typically, the system is wired up to use the neutral line as 0V. That comes from the building power supply. In theory, that neutral wire should always read as 0V. In practice, other equipment in the electrical system creates small fluctuations in that wire. Sometimes it jumps up to 250mV. Sometimes less. Such fluctuations are harmless for building power supply. But that disturbance makes a massive difference as our reference voltage.

So, power quality is critical on the carriage. I would consider a local UPS supply along with transient isolators on the neutral power lines. In addition, all power cables and signal cables need to be shielded, with the shields grounded. The data acquisition system can also employ differential inputs to mitigate any interference from the neutral line.

As if the power supply wasn’t bad enough, the drive motors for the carriage generate huge electromagnetic interference. (EMI) Without precautions, motors induce massive amounts of noise on the signal wires. I once worked in a towing tank that had a wind tunnel next door, with massive motor to operate their fan. You would think we were safe from EMI. The motor sat 20 ft. away through two solid brick walls. Yet when that motor started, it generated so much EMI that we lost all signal quality in the towing tank. Thankfully, the motors on your towing carriage don’t carry as much power, but they are a lot closer than 20 ft. Expect EMI.

The first answer to EMI: shield the wires. You can buy shielded wire, which includes a layer of metal foil wrapped around the wires. But shielding on the wires doesn’t completely eliminate this problem. We need to be very careful with the layout of electrical wires on the carriage. Avoid any parallel paths between the drive motors and the signal cables.

Carriage Maintenance

It’s very hard to work on the bottom of the carriage when it’s always over water. It helps if we can extend the carriage rails past the water flume. Create a maintenance section where we bring the carriage over dry land for maintenance. It also helps to have rails for an overhead crane at this location. We use the overhead crane to move in ship models (they may weigh several hundred pounds). But also to remove equipment from the towing carriage. Heavy industrial equipment, like the drive motors. This towing tank will last 50+ years. At some point in the carriage’s lifetime, we will need to replace the drive motors . . . and every other major component.

Support Facilities

The towing tank requires a lot more than just a bath of water. There are several other support facilities that need to be included.

Trim Tank

When we put ship models in the towing tank, we also need to match the weight and center of gravity for the model. Normally, the ship models are built lighter than the design weight. We then add weights to the model and balance it before attaching to the towing carriage. This is normally done in a trim tank.

Figure 5‑1: Example of Trim Tank

The trim tank is usually attached to the main towing tank, extending behind the beach. We build a shallow basin, only 2-3 ft deep. In some tanks, we also attach the model to the towing carriage from inside the trim tank. That assumes the towing carriage can travel back to the trim tank. The main problem is normally the beach in the main towing tank. That beach typically extends above waterline. So, it blocks the path of trying to move the model from the trim tank out into the main tank.

I saw several improvised solutions that built a work platform on the main beach. That never seems like a good answer to me. I would prefer to place the main beach on a hinge so that we can lower the beach below water level to pass the model in to the main tank.

Also, we typically want 2 or 3 trim tanks. This allows the towing tank to work with 2 or 3 different models at the same time. You can have one model in testing, model 2 just finished testing and has paint drying, and model 3 is getting ready to test. Three different stages of using a model, three different models, and three different trim tanks. It adds flexibility. Important to consider since the trim tanks are formed from cast concrete along with the rest of the flume. We only get to do this once.

Calibration Facilities

Every last sensor needs to be calibrated. The calibration establishes the relationship between the voltage seen by the data acquisition system and whatever quantity that sensor measures. Calibration and sensor quality checks are a continuous task in a towing tank.

So, we need calibration facilities on the towing carriage and back on land. These facilities include calibration test stands, designed to impart specific forces or deflection to sensors. And calibration requires a reliable set of NIST certified measurement equipment (test weights, displacement measurement and angular measurement).

But then we need a convenient way to apply those calibration loads when all the sensors are installed on the towing carriage. This is especially important for the tow post. The tow post will include fittings and pulleys to redirect the force from the calibration weights into a horizontal force on the load cells. Simple enough, but something that you need to consider from the beginning of the design.

Model Fabrication

Some towing tanks have their own model fabrication facilities. This isn’t strictly a requirement. Many towing tanks will contract to a vendor for the model fabrication.

Model Verification

Some commercial tanks include the ability to verify the model dimensions. This requires a 3D robotic probe. Basically, a 3D CNC robot with a touch probe to confirm model coordinates down to an accuracy of less than a millimeter.

Model Handling and Storage

These models get heavy. There should be a wheeled cart capable of transporting the models from a loading dock to the towing tank. We also have need for an overhead crane rail with a chainfall to lift the model into the towing tank.

Model storage is also necessary. Most towing tanks store a few standard test models to validate accuracy of the towing tank. They need a place for storage. We may also store models from individual tests. The most common location for storage is a set of shelves along the walls on one side of the towing tank.

Open Space

We also need a wide open workspace at one end of the towing tank. Space for a workshop, workbench, tool storage. Storage shelves and bins. A lot of tank testing requires improvised solutions and troubleshooting during the test. A small workshop greatly facilities this work. And duct tape. Duct tape is the universal tool for improvised solutions in the towing tank. So much duct tape.

Conclusion

Taken all together, this adds up to a very daunting shopping list. Tons of components to source and buy. But notice that very little of it involved complicated equations or esoteric theories. There are no secrets to buying light bulbs. You don’t need to be a genius when shopping for a towing tank. Most of the vendors already have that specialized knowledge. They stand ready to help, provided you ask the right questions. That was the goal for this shopping list. Armed with this introduction, you know what to search for, when to look for specialists, which questions to ask. Granted, it’s still a long shopping list, but an accessible one. Start with the first question and keep working until the last one. And feel to call DMS if you want some help. You got this.

References

| [1] | HR Wallingford, “Wave Generation Systems at HR Wallingford,” YouTube, 6 Sep 2017. [Online]. Available: https://youtu.be/KZanGVCLHzI?si=7hYGE6tlcDC7MVa6. [Accessed 5 May 2025]. |

| [2] | H. Cho, “KITECH Marine Robot Center basin and towing carriage,” YouTube, 15 Aug 2022. [Online]. Available: https://youtu.be/LhXOUWHrtkw?si=wnDwDJcPSRoAAogp. [Accessed 5 May 2025]. |

| [3] | MHL Media, “What it Takes to Clean a Towing Tank – Summer 2022,” YouTube, 19 Aug 2022. [Online]. Available: https://youtu.be/O2JzGNiIMBU?si=u8678e2FmPNjRxuT. [Accessed 5 May 2025]. |

| [4] | B. M. e. Al., “DESIGN, DEVELOPMENT AND COMMISSIONING OF THE BOLDREWOOD TOWING,” Transactions of the Royal Institute of Naval Architects, vol. A2, 2023. |

| [5] | Engineering, University of Southampton, “Using the towing tank in your Ship Science degree,” YouTube, 03 Dec 2021. [Online]. Available: https://www.youtube.com/watch?v=71ZwlsXCa3Q&ab_channel=Engineering%2CUniversityofSouthampton. [Accessed 05 Aug 2025]. |

| [6] | MHL Media, “What it Takes to Clean a Towing Tank – Summer 2022,” YouTube, 19 Aug 2022. [Online]. Available: https://www.youtube.com/watch?v=O2JzGNiIMBU&t=3s&ab_channel=MHLMedia. [Accessed 05 Aug 2025]. |

| [7] | Boldrewood Towing Tank, “The Boldrewood Towing Tank,” YouTube, 23 May 2022. [Online]. Available: https://www.youtube.com/watch?v=Q9qZcN5iX2k&t=26s&ab_channel=BoldrewoodTowingTank. [Accessed 05 Aug 2025]. |

| [8] | Technimove, “Technimove – Environment Re-Cabling (Before & After),” YouTube, 01 Aug 2018. [Online]. Available: https://www.youtube.com/watch?v=gI2XA_4H04A&ab_channel=Technimove. [Accessed 05 Aug 2025]. |

| [9] | The Civil Department, “Data Acquisition System | Lab test | Data collection | Lab in civil Engineering | Abhishek Bhushan,” YouTube, 06 Jun 2023. [Online]. Available: https://www.youtube.com/watch?v=jUqjkE-NuuM&ab_channel=TheCivilDepartment. [Accessed 05 Aug 2025]. |

| [10] | HR Wallingford, “HR Wallingford wavemaker’s demonstrating our active absorption system,” YouTube, 26 May 2020. [Online]. Available: https://www.youtube.com/watch?v=512icxZoK2U&ab_channel=HRWallingford. [Accessed 05 Aug 2025]. |

| [11] | Electronics Notes, “What is PXI, PXIe, & PXImc – understanding the fundamentals,” YouTube, 13 Feb 2018. [Online]. Available: https://www.youtube.com/watch?v=k_JrU75M4s8&list=WL&index=46&t=1s&ab_channel=ElectronicsNotes. [Accessed 06 Aug 2025]. |

| [12] | Nortek, “Oceanography: How wave orbital velocities attenuate with depth,” YouTube, 24 Apr 2023. [Online]. Available: https://www.youtube.com/watch?v=xGGnMIW8CfY&ab_channel=Nortek. [Accessed 06 Aug 2025]. |

| [13] | MrBerniebling HVAC Chiller Mechanic, “Large commercial pool backwash issue,” YouTube, 25 Jun 2022. [Online]. Available: https://www.youtube.com/watch?v=5vzVSnPk2GA&ab_channel=MrBernieblingHVACChillerMechanic. [Accessed 06 Aug 2025]. |