https://dmsonline.us/wp-content/uploads/2023/12/HabbakukCover-Small-1.jpg

489

500

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-09-24 09:18:002026-02-20 09:08:57Project Habbakuk: A Ship from Ice!

https://dmsonline.us/wp-content/uploads/2023/12/HabbakukCover-Small-1.jpg

489

500

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-09-24 09:18:002026-02-20 09:08:57Project Habbakuk: A Ship from Ice!1.0 Introduction

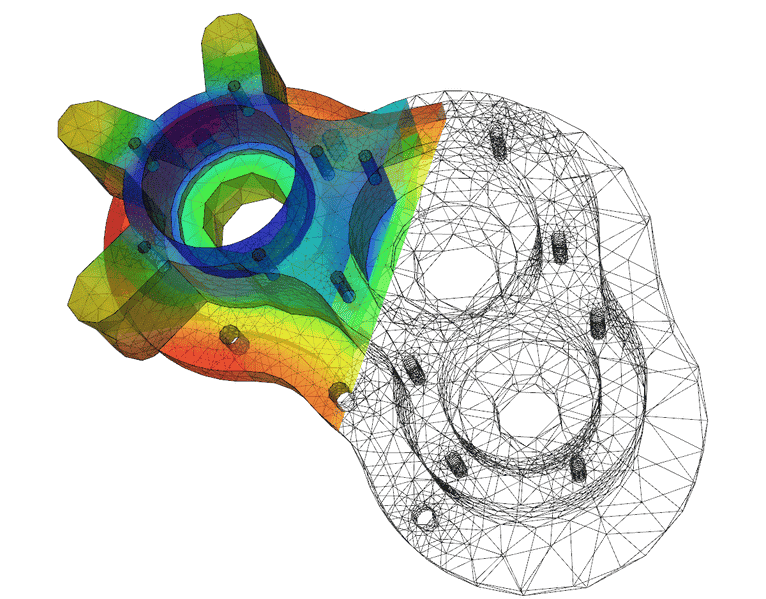

Finite Element Analysis (FEA). You want it. But where to start? How does FEA work? How to pick the right provider. FEA requires more than just software. It needs a background in the science, the mathematics, and the process from start to finish. That knowledge is a daunting task just to hire a service provider for the FEA. Neither should we purchase FEA with no foreknowledge. Today we arm the clever consumer with a five minute introduction to FEA and where to apply it.

2.0 What Is FEA?

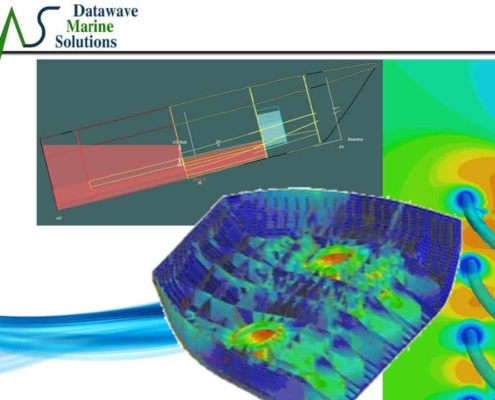

In Finite Element Analysis (FEA), we use the computer to solve generalized structural engineering problems. The generality of FEA offers the real advantage. Classic structural analysis requires us to derive equations for prescribed scenarios, each customized to a specific structure and geometry. But in FEA, we divide the structure into many thousands of tiny little pieces, called a mesh. We employ generalized equations to describe how all those pieces interact with each other. The computer solves all those interactions to provide predictions of stresses and numerous other structural details. By using the computer and one very fancy equation, FEA delivers the promise of generalized structural analysis.

But this promise comes at a price. FEA can get the answer wrong. From the computer’s perspective, FEA is just a giant Sudoku puzzle. (Figure 2‑1) The computer does not know if the puzzle solution provides useful information for the real world. That job falls to the FEA engineer. The engineer performs extensive QA to ensure the computer accurately predicts reality.

Human Sudoku |

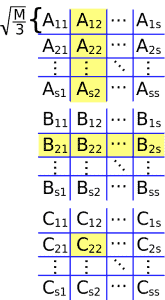

![FEA Matrix [1] (Computer Sudoku)](https://dmsonline.us/wp-content/uploads/2021/06/Block_matrix_multiplication.svg-165x300-1.png) FEA Matrix [1] (Computer Sudoku) |

3.0 Where Can I Use FEA?

FEA applies to any form of structural analysis. Use it to design the global structure for your ship, or the smallest padeye for lifting a rescue boat. It also applies to thermal analysis. Optimize heat transfer through a complex heat exchanger. Or even combine the two disciplines. Imagine carrying hot asphalt in a barge. FEA can predict the heat dissipation and thermal expansion of the hull structure. That could be a very specific and complicated problem with classic structural engineering. But FEA makes it standard.

The bonus value of FEA does not derive from the arena of application, but from its exceptional output. Traditionally, design only answered the question of what. What is my stress? Did I pass. FEA also tells you why. And that extra knowledge brings the opportunity to improve the situation. Use FEA when you want to optimize your structure. Some good examples:

- Use FEA to optimize the design template for a transverse bulkhead. Some optimization here creates major weight savings when applied to all bulkheads.

- Design the foundations for a crane pedestal.

- Check global strength of the entire vessel hull.

- Predict fatigue lifetime for critical leg structures on a jackup rig.

- Minimize structural vibrations and ensure your ship doesn’t resonate with the engine.

3.1 Where Should I Avoid FEA?

FEA is impressive, but expensive. Don’t waste your entire budget on unnecessary FEA. Classic structural analysis still works fine for many cases. Simple cases do not need FEA, and no analysis will magically save money on a structure that was already optimized. Some examples of when to avoid FEA:

- Simulate every second of a 30 year fatigue life in FEA

- WAY too expensive

- Scantling calculations

- Concept design of structure

- Too many radical changes in geometry for efficient FEA

- Simple beam bending calculations

- Simple plate bending calculations

- Simple stanchion buckling problems

FEA is like going to a specialist doctor instead of your general physician. You come to the specialist with concerns about a specific problem, not general questions about your health. And the specialist normally happens after the general doctor. Similarly, FEA is the second option for tackling structural problems. Not your first choice, but a valuable support for special cases.

4.0 Conclusion

Finite Element Analysis (FEA). The applications. The science. You don’t need expertise to benefit from FEA services. The engineer delivers all that background knowledge wrapped into a tidy report. But we all benefit from a basic understanding of the process and applications. Begin with reasonable expectations for an FEA analysis and monitor with an understanding of the overall process. Then FEA gets demystified. It reduces from dangerous wizard’s magic into just another tool in your toolbox.

6.0 References

| [1] | Dcoetzee, “Block Matrix Multiplication,” Wikimedia Commons, 4 Sep 2012. . Available: https://commons.wikimedia.org/wiki/File:Block_matrix_multiplication.svg. . |

| [2] | U. A1, “Elmer Pump Heat Equation,” Wikimedia Commons, 2 Jun 2010. . Available: https://commons.wikimedia.org/wiki/File:Elmer-pump-heatequation.png. . |

Share This Post

More Like This

https://dmsonline.us/wp-content/uploads/2023/12/HabbakukCover-Small-1.jpg

489

500

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-09-24 09:18:002026-02-20 09:08:57Project Habbakuk: A Ship from Ice!

https://dmsonline.us/wp-content/uploads/2023/12/HabbakukCover-Small-1.jpg

489

500

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-09-24 09:18:002026-02-20 09:08:57Project Habbakuk: A Ship from Ice! https://dmsonline.us/wp-content/uploads/2023/12/Icebreaker_SpoonBow.webp

217

598

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-07-16 09:00:002026-02-20 09:08:58Strong as Ice: Icebreaker Structure

https://dmsonline.us/wp-content/uploads/2023/12/Icebreaker_SpoonBow.webp

217

598

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-07-16 09:00:002026-02-20 09:08:58Strong as Ice: Icebreaker Structure

Surviving the Arctic: Polar Class Icebreakers

Design Support, Fluids, Mechanical, Propulsion, Special Purpose Mechanical Systems, Structural

Ramming the Ice: Icebreaker Propulsion

Energy Generation, Fluids, Hull Structure, Propulsion, Propulsion Plant, Propulsion Units, Propulsors, Structural, Transmission and Propulsor Systems https://dmsonline.us/wp-content/uploads/2023/12/MackinawIce2-scaled-1.jpg

1200

985

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-01-16 09:00:002026-02-20 09:08:58Breaking the Ice: Icebreakers

https://dmsonline.us/wp-content/uploads/2023/12/MackinawIce2-scaled-1.jpg

1200

985

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2024-01-16 09:00:002026-02-20 09:08:58Breaking the Ice: Icebreakers https://dmsonline.us/wp-content/uploads/2022/06/MVAltairGeneralArrangementPlan_SmallResolution.webp

299

640

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

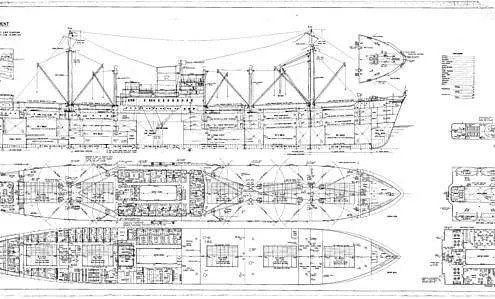

Nate Riggins2022-09-12 06:00:002025-09-30 07:31:20How to Design a Ship

https://dmsonline.us/wp-content/uploads/2022/06/MVAltairGeneralArrangementPlan_SmallResolution.webp

299

640

Nate Riggins

/wp-content/uploads/2025/06/DMS-logo.svg

Nate Riggins2022-09-12 06:00:002025-09-30 07:31:20How to Design a Ship

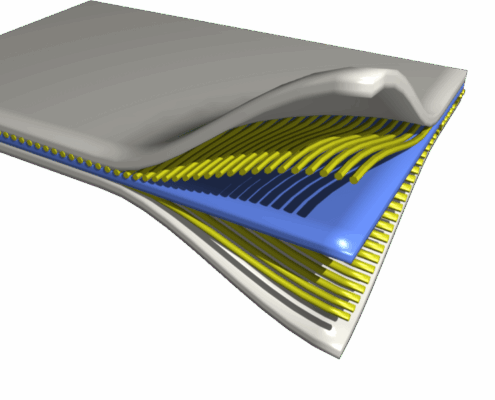

Composite Materials

Engineering Business, Hull Structure, Materials, Special Purpose Structure, Structural

Six Ways to Break the Ship

Elastic Static Loading, Fatigue, FEA / Numerical Methods, Hull Decks, Hull Structural Bulkheads, Hull Structure, Masts, Kingposts, Service Platforms, Shell and Supporting Structure, Special Methods, Special Purpose Structure, Structural

Improve Engineering Value

3D Modeling, Arrangements, Drafting, Engineering Business, Fatigue, FEA / Numerical Methods, Fluid Dynamics, Fluids, Fluids Special Methods, Hull Structure, Hydrostatics, StructuralAbout Us

Ship designs tailored to your mission. Engineering that advances profits.