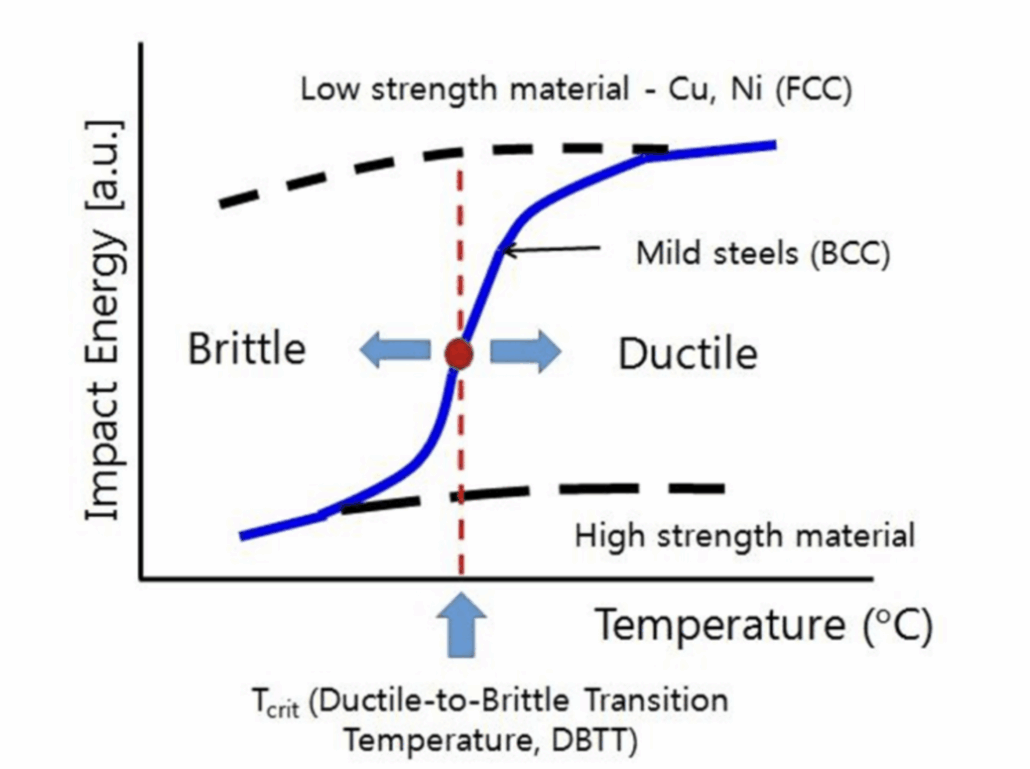

Given the need to create strong structures with light weight, you might think we immediately go to the highest strength steel we can find. But no. Higher strength steels come with trade-offs. They tend to become more brittle. We want ductile, flexible steel. When a chunk of ice hits, we want the steel to flex and bend, not crack and break. Brittle steel spells doom for icebreaking.

And in cold water, normally ductile steel can become brittle. Below a transition temperature, the steel stops behaving in a ductile manner and acts brittle. (Figure 5‑1) And that transition temperature hovers around the same point as cold polar temperatures. Normal mild steel transitions around -15C [5] Icebreakers definitely experience temperatures below the freezing point of water (0C), or we wouldn’t have ice!

Now, structural design goes beyond simple strength of steel; we also need to consider the impact energy, at cold temperatures. Simplifying all the science, more impact energy at lower temperatures equals more ductility. We can test this in the lab, after freezing our samples to low temperature conditions. Despite our need for high strength steel, the impact energy may govern our selection for steel properties. We may choose a low strength steel to ensure it remains ductile and survives decades of abuse as an icebreaker.